sealed Crimp, Solder & see connectors

Features & Benefits

Take the guesswork out of soldering!

The objective of the thermal indicator is to provide the installer with an additional visual cue of the solder sleeve transforming and flowing into the crimp barrel window. The most common mistake using solder connectors is not heating the solder enough, creating a cold solder joint (inferior termination). To prevent a cold solder joint, the red dye offers an extra visual cue for the installerto continue applying heat to the solder connector, ensuring maximum tensile strength & conductivity.

Uninstalled

Mid Install

Installed

Cut-Away

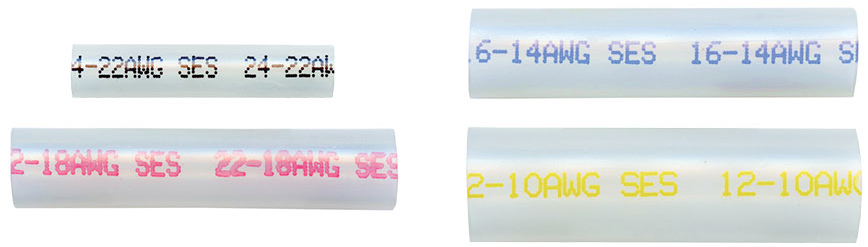

Clear Adhesive-Lined Heat Shrink Tubing

- Clear tubing allows optimal visual inspection

- Color-coded print on tubing

Improved adhesive provides stronger seal

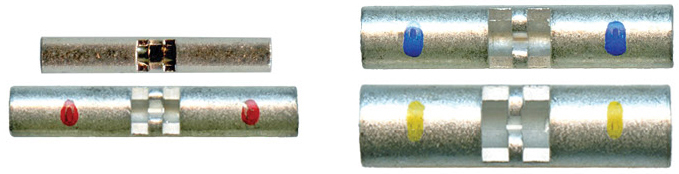

Window Butt Connectors

- Seamless barrel with window and wire stop

- Window positioned between color-coded dots, 3 primary sizes

- Orient color-coded dots where they are visible to see solder flow

Thermal Indicator Solder Sleeve

- Red thermal indicator disappears from solder sleeve when solder has flowed.

- Lead free solder alloy has greater surface tension

- “No-clean” flux on solder sleeve cleans metals &

provides quality solder termination.

NEW: Thermal Indicator Solder Sleeve

Existing Solder Sleeve