sealed solder connectors

Features & Benefits

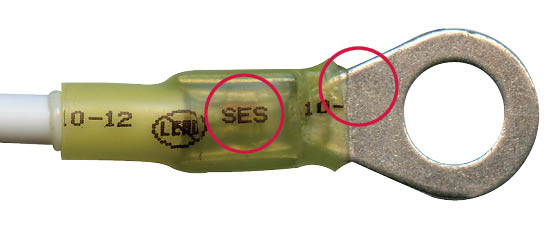

Sealed Solder Connectors provide a high quality, sealed solder connection that takes the guesswork out of soldering. Soldered terminations provide superior tensile strength and conductivity. Don’t settle for ANY connector … demand Sealed Solder Connectors!

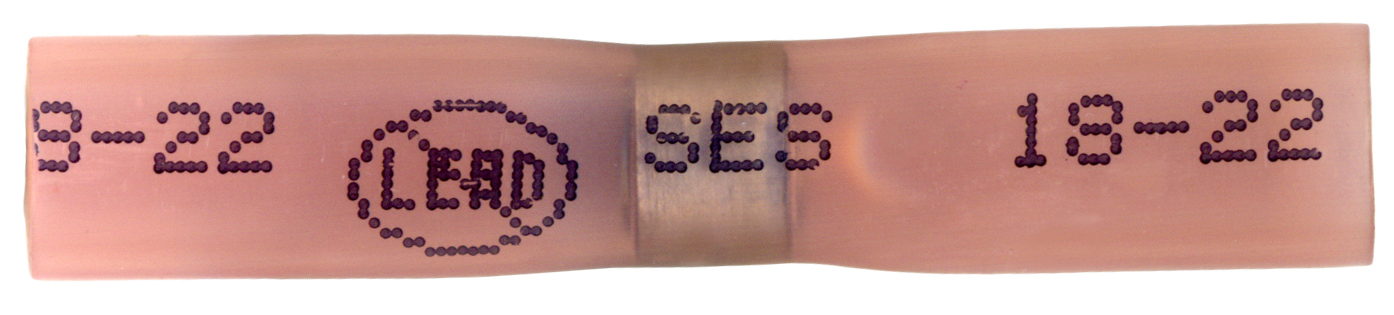

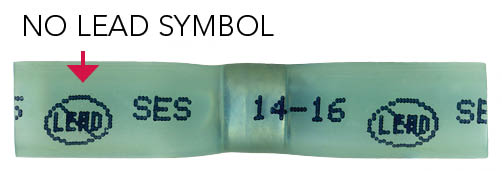

- Lead free solder has greater surface tension

- Solder stays in place which provides greater tensile strength than other solder sleeves

- New solder much less likely to run out of the tubing

- Solder sleeves pre-fluxed to clean metals & provide a quality solder termination

- Original solder can become runny

- New Solder has greater surface tension – less runny

- New lead free solder has lower melt temperature (138°C vs 145°C)

- New solder sleeves are Tin & Bismuth alloy

- Other solder sleeves contain both Lead & Cadmium

- New solder – RoHS compliant

- Better for the environment