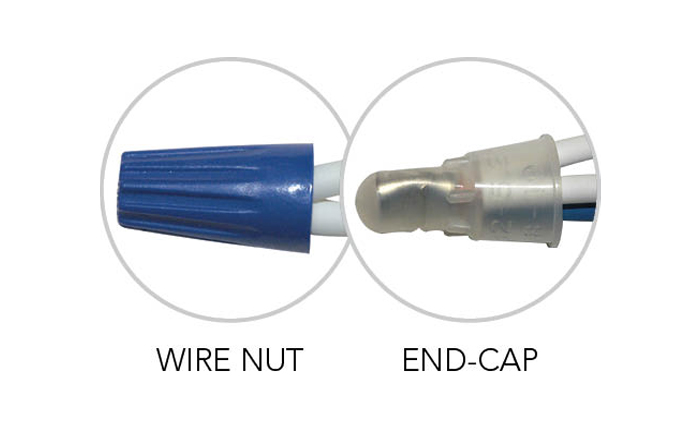

sealed multiple Wire connectors

Features & Benefits

In-Line Butt

Connectors

Closed-End Connectors

Join One to Two Wires

Join Two to Four Wires

NSPA Version

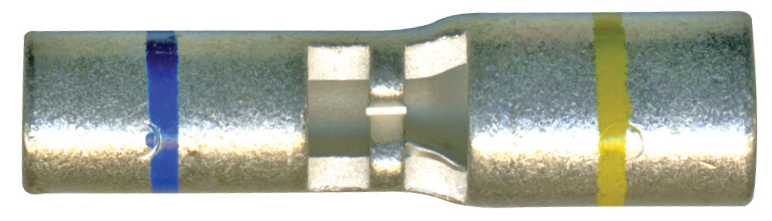

The barrel has two stripes – one on each end – to indicate where to crimp the connector. Plus, the stripe matches the crimp die that needs to be used. Easy to crimp & provides strong crimp termination!

- Window for visual inspection

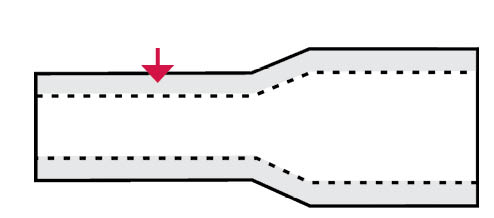

- The inside AND the outside diameter of the connector is varied which means that both sides will make a sound mechanical crimp.

- Uniform copper wall – EASY to crimp

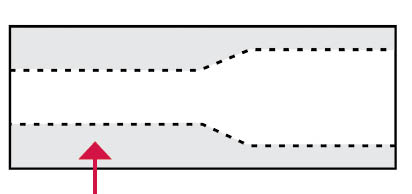

Competitors Version

The outside diameter of the butt connector is the same on both ends and only the inside diameter is adjusted for the different wire gauge. This means that the side for the smaller wire has a much thicker wall than normal and is extremely difficult to crimp. Almost impossible to crimp properly & wire can easily pull out!!

- Thick copper wall – Difficult to crimp

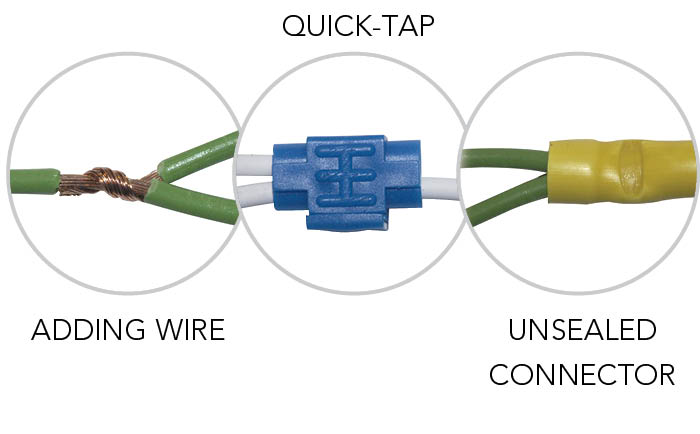

Existing Problems with Traditional In-Line Connectors

- In environments where corrosion and/or

vibration are a problem, the closed-end

connector can be used to replace wire nuts and other similar connectors. - Tubing has an active adhesive that seals multiple wires and eliminates wire pull-out

Existing Problems with Traditional Closed-End Connectors

Additional features of the NSPA Step Down Butt Connector

- Seamless butt connectors provide superior crimp performance

- Window in butt connectors allows for visual inspection to ensure all wires are fully inserted

- Butt connectors have crimp indicators where the installation tool should be positioned to crimp connector

- Wire-stop in butt connector prevents over-insertion of the wires

The Heat Shrink Tubing

- High adhesive-flow polyolefin tubing to seal multiple wires

- Color-coded dash on tubing to indicate the wire gauge for the connector

- Clear tubing to allow for visual inspection

- 4 to 1 Shrink Ratio