sealed crimp connectors

Features & Benefits

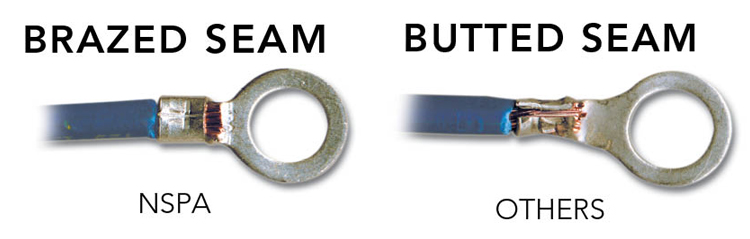

Butted Seam Connectors

Formed when metal is stamped, rolled, and butted to create the connector barrel. Should only be used with stranded wire and must be crimped in the proper place to avoid opening the seam.

Brazed Seam Connectors

Formed much like a butted seam, except the seam is brazed together with a solder alloy. May be used with solid or stranded wire and can be crimped on any side of the barrel without opening the seam.

Seamless Connectors

Generally only available for a butt connector or splice. The barrel is created from one seamless piece of metal. This eliminates problem of the barrel opening. May be used with solid or stranded wire.

Brazed Seam & Seamless Connector Advantages

• Better wire contact

• Less voltage drop

• Increases current flow

• Superior tensile strength

• Prevents wiring failures

• Reduces equipment downtime

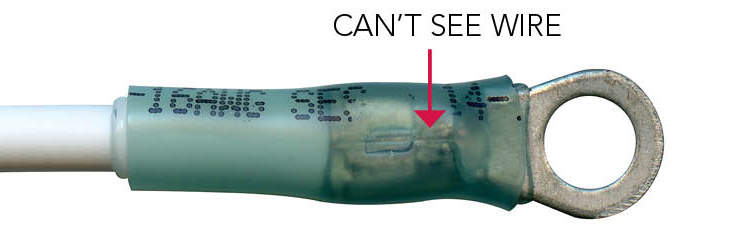

Never designed to be insulated with heat shrink tubing

Often a poor seal or tubing impedes stud hole

Traditional barrel, user can’t see that the wire is fully inserted so unsure if wire is crimped to barrel

Other heat shrink ring terminals aren’t designed to be stacked .. tubing impedes electrical contact

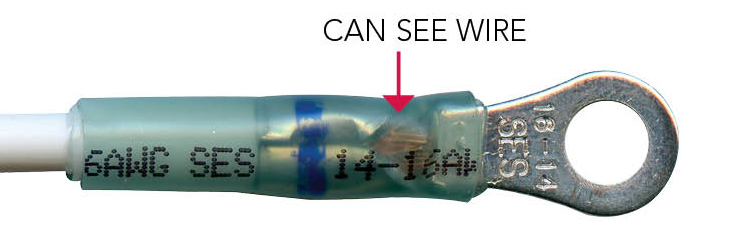

Our Sealed Long Neck Terminals are designed to ensure a proper seal and has a 45° barrel to allow installer to see that the wire is fully inserted.

45° barrel allows installer to see wire is fully inserted and wire is crimped to barrel

45° barrel ensures wire is stripped proper length

Long neck allows ring terminals to be stacked with maximum contact