sealed Crimp & solder connectors

Features & Benefits

Sealed Crimp & Solder Connectors are crimped for mechanical reliability, soldered for superior strength and conductivity, and sealed for maximum durability. When there is no margin for error, choose Sealed Crimp & Solder Connectors…the ultimate connector.

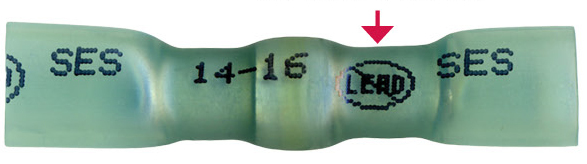

- Lead free solder has greater surface tension

- Solder stays in place which provides greater tensile strength than other solder sleeves

- New solder much less likely to run out of the tubing

- Solder sleeves pre-fluxed to clean metals & provide a quality solder termination

Installs faster

- New lead free solder has lower melt temperature (138°C vs 145°C)

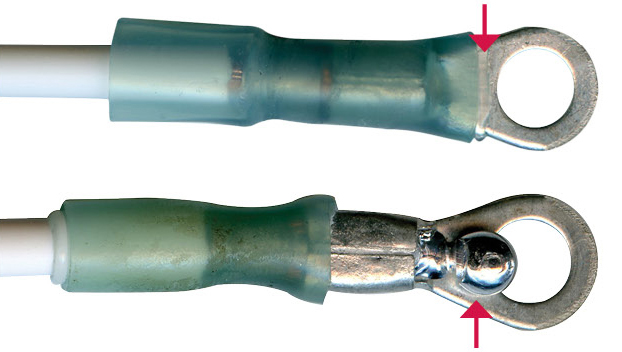

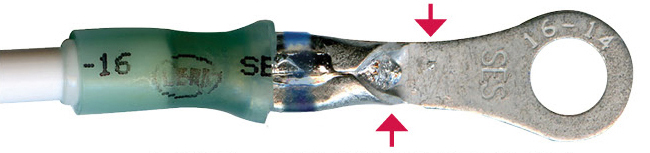

Original Terminal

Tubing impedes flush surface

Original solder can become runny

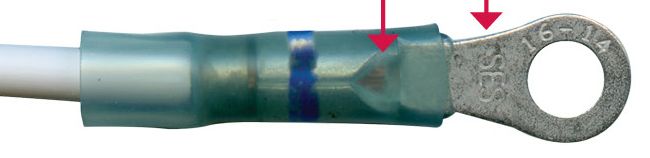

New & Improved Lead Free Terminal

Can see wire New, longer neck

New Solder, Less Runny

45 degree barrel – Can see solder flow